|

ASPECT

|

|

ASPECT

|

Static Public Member Functions | |

| static void | declare_parameters (ParameterHandler &prm) |

Static Public Member Functions inherited from aspect::Plugins::InterfaceBase Static Public Member Functions inherited from aspect::Plugins::InterfaceBase | |

| static void | declare_parameters (ParameterHandler &prm) |

Static Public Member Functions inherited from aspect::SimulatorAccess< dim > Static Public Member Functions inherited from aspect::SimulatorAccess< dim > | |

| static void | get_composition_values_at_q_point (const std::vector< std::vector< double >> &composition_values, const unsigned int q, std::vector< double > &composition_values_at_q_point) |

Private Attributes | |

| std::unique_ptr< Rheology::ViscoPlastic< dim > > | rheology |

| std::vector< double > | thermal_diffusivities |

| bool | define_conductivities |

| std::vector< double > | thermal_conductivities |

| std::vector< unsigned int > | n_phase_transitions_for_each_chemical_composition |

| unsigned int | n_phases |

| EquationOfState::MulticomponentIncompressible< dim > | equation_of_state |

| MaterialUtilities::PhaseFunction< dim > | phase_function |

| bool | use_dominant_phase_for_viscosity |

| std::unique_ptr< MaterialUtilities::PhaseFunctionDiscrete< dim > > | phase_function_discrete |

Additional Inherited Members | |

Public Types inherited from aspect::MaterialModel::Interface< dim > Public Types inherited from aspect::MaterialModel::Interface< dim > | |

| using | MaterialModelInputs = MaterialModel::MaterialModelInputs< dim > |

| using | MaterialModelOutputs = MaterialModel::MaterialModelOutputs< dim > |

Protected Attributes inherited from aspect::MaterialModel::Interface< dim > Protected Attributes inherited from aspect::MaterialModel::Interface< dim > | |

| NonlinearDependence::ModelDependence | model_dependence |

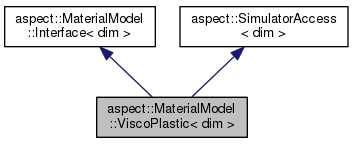

A material model combining viscous and plastic deformation, with the option to also include viscoelastic deformation.

Viscous deformation is defined by a viscous flow law describing dislocation and diffusion creep: \( v = \frac{1}{2} A^{-\frac{1}{n}} d^{\frac{m}{n}} \dot{\varepsilon}_{ii}^{\frac{1-n}{n}} \exp\left(\frac{E + PV}{nRT}\right) \) where where \(A\) is the prefactor, \(n\) is the stress exponent, \(\dot{\varepsilon}_{ii}\) is the square root of the deviatoric strain rate tensor second invariant, \(d\) is grain size, \(m\) is the grain size exponent, \(E\) is activation energy, \(V\) is activation volume, \(P\) is pressure, \(R\) is the gas exponent and \(T\) is temperature.

One may select to use the diffusion ( \(v_{diff}\); \(n=1\), \(m!=0\)), dislocation ( \(v_{disl}\), \(n>1\), \(m=0\)) or composite \(\frac{v_{diff}v_{disl}}{v_{diff}+v_{disl}}\) equation form.

Viscous stress is limited by plastic deformation, which follows a Drucker Prager yield criterion: \(\sigma_y = C\cos(\phi) + P\sin(\phi)\) (2D) or in 3D \(\sigma_y = \frac{6C\cos(\phi) + 2P\sin(\phi)}{\sqrt{3}(3+\sin(\phi))}\) where \(\sigma_y\) is the yield stress, \(C\) is cohesion, \(phi\) is the angle of internal friction and \(P\) is pressure. If the viscous stress ( \(2v{\varepsilon}_{ii})\)) exceeds the yield stress ( \(\sigma_{y}\)), the viscosity is rescaled back to the yield surface: \(v_{y}=\sigma_{y}/(2{\varepsilon}_{ii})\)

When included, the viscoelastic rheology takes into account the elastic shear strength (e.g., shear modulus), while the tensile and volumetric strength (e.g., Young's and bulk modulus) are not considered. The model is incompressible and allows specifying an arbitrary number of compositional fields, where each field represents a different rock type or component of the viscoelastic stress tensor. The symmetric stress tensor in 2D and 3D, respectively, contains 3 or 6 components. The compositional fields representing these components must be named and listed in a very specific format, which is designed to minimize mislabeling stress tensor components as distinct 'compositional rock types' (or vice versa). For 2D models, 3+3 consecutive compositional fields must be labeled ve_stress_xx, ve_stress_yy ve_stress_xy, ve_stress_xx_old, ve_stress_yy_old, ve_stress_xy_old. In 3D, six consecutive compositional fields must be labeled ve_stress_xx, ve_stress_yy, ve_stress_zz, ve_stress_xy, ve_stress_xz, ve_stress_yz, ve_stress_xx_old, ve_stress_yy_old, ve_stress_zz_old, ve_stress_xy_old, ve_stress_xz_old, ve_stress_yz_old.

Combining this viscoelasticity implementation with non-linear viscous flow and plasticity produces a constitutive relationship commonly referred to as partial elastoviscoplastic (e.g., pEVP) in the geodynamics community. While extensively discussed and applied within the geodynamics literature, notable references include: Moresi et al. (2003), J. Comp. Phys., v. 184, p. 476-497. Gerya and Yuen (2007), Phys. Earth. Planet. Inter., v. 163, p. 83-105. Gerya (2010), Introduction to Numerical Geodynamic Modeling. Kaus (2010), Tectonophysics, v. 484, p. 36-47. Choi et al. (2013), J. Geophys. Res., v. 118, p. 2429-2444. Keller et al. (2013), Geophys. J. Int., v. 195, p. 1406-1442.

The overview below directly follows Moresi et al. (2003) eqns. 23-32. However, an important distinction between this material model and the studies above is the option to use compositional fields, rather than particles, to track individual components of the viscoelastic stress tensor. Calculating viscoelastic stresses with particles is also implemented, and can be switched on by using particles with the particle property 'elastic stress'. Moresi et al. (2003) begins (eqn. 23) by writing the deviatoric rate of deformation ( \(\hat{D}\)) as the sum of elastic ( \(\hat{D_{e}}\)) and viscous ( \(\hat{D_{v}}\)) components: \(\hat{D} = \hat{D_{e}} + \hat{D_{v}}\). These terms further decompose into \(\hat{D_{v}} = \frac{\tau}{2\eta}\) and \(\hat{D_{e}} = \frac{\overset{\triangledown}{\tau}}{2\mu}\), where \(\tau\) is the viscous deviatoric stress, \(\eta\) is the shear viscosity, \(\mu\) is the shear modulus and \(\overset{\triangledown}{\tau}\) is the Jaumann corotational stress rate. If plasticity is included the deviatoric rate of deformation may be written as: \(\hat{D} = \hat{D_{e}} + \hat{D_{v}} + \hat{D_{p}}\), where \(\hat{D_{p}}\) is the plastic component. As defined in the second paragraph, \(\hat{D_{p}}\) decomposes to \(\frac{\tau_{y}}{2\eta_{y}}\), where \(\tau_{y}\) is the yield stress and \(\eta_{y}\) is the viscosity rescaled to the yield surface.

Above, the Jaumann corotational stress rate (eqn. 24) from the elastic component contains the time derivative of the deviatoric stress ( \(\dot{\tau}\)) and terms that account for material spin (e.g., rotation) due to advection: \(\overset{\triangledown}{\tau} = \dot{\tau} + {\tau}W -W\tau\). Above, \(W\) is the material spin tensor (eqn. 25): \(W_{ij} = \frac{1}{2} \left (\frac{\partial V_{i}}{\partial x_{j}} - \frac{\partial V_{j}}{\partial x_{i}} \right )\).

The Jaumann stress-rate can also be approximated using terms from the time at the previous time step ( \(t\)) and current time step ( \(t + \Delta t^{e}\)): \(\smash[t]{\overset{\triangledown}{\tau}}^{t + \Delta t^{e}} \approx \frac{\tau^{t + \Delta t^{e} - \tau^{t}}}{\Delta t^{e}} - W^{t}\tau^{t} + \tau^{t}W^{t}\). In this material model, the size of the time step above ( \(\Delta t^{e}\)) can be specified as the numerical time step size or an independent fixed time step. If the latter case is selected, a stress averaging scheme is applied to account for the differences between the numerical and fixed elastic time step (eqn. 32). A fixed computational time step throughout the model run can be achieved by using a large CFL number and smaller maximum time step values that restrict the numerical time step to a specific value.

The formulation above allows rewriting the total rate of deformation (eqn. 29) as \(\tau^{t + \Delta t^{e}} = \eta_{eff} \left ( 2\hat{D}^{t + \triangle t^{e}} + \frac{\tau^{t}}{\mu \Delta t^{e}} + \frac{W^{t}\tau^{t} - \tau^{t}W^{t}}{\mu} \right )\).

The effective viscosity (eqn. 28) is a function of the viscosity ( \(\eta\)), elastic time step size ( \(\Delta t^{e}\)) and shear relaxation time ( \( \alpha = \frac{\eta}{\mu} \)): \(\eta_{eff} = \eta \frac{\Delta t^{e}}{\Delta t^{e} + \alpha}\) The magnitude of the shear modulus thus controls how much the effective viscosity is reduced relative to the initial viscosity.

Elastic effects are introduced into the governing Stokes equations through an elastic force term (eqn. 30 updated to the term in eqn. 5 in Farrington et al. 2014) using stresses from the previous time step rotated and advected into the current time step: \(F^{e,t} = -\frac{\eta_{eff}}{\mu \Delta t^{e}} \tau^{0adv}\). This force term is added onto the right-hand side force vector in the system of equations.

Several model parameters (reference densities, thermal expansivities thermal diffusivities, heat capacities and rheology parameters) can be defined per-compositional field. For each material parameter the user supplies a comma delimited list of length N+1, where N is the number of compositional fields. The additional field corresponds to the value for background material. They should be ordered ``background, composition1, composition2...''

If a list of values is given for the density, thermal expansivity, thermal diffusivity and heat capacity, the volume weighted sum of the values of each of the compositional fields is used in their place, for example \(\rho = \sum \left( \rho_i V_i \right)\)

The individual output viscosities for each compositional field are also averaged. The user can choose from a range of options for this viscosity averaging. If only one value is given for any of these parameters, all compositions are assigned the same value. The first value in the list is the value assigned to "background material" (regions where the sum of the compositional fields is < 1.0).

Definition at line 184 of file visco_plastic.h.

|

overridevirtual |

Initialization function. Loads the material data and sets up pointers if it is required.

Reimplemented from aspect::Plugins::InterfaceBase.

|

overridevirtual |

Function to compute the material properties in out given the inputs in in.

Implements aspect::MaterialModel::Interface< dim >.

|

overridevirtual |

Return whether the model is compressible or not. Incompressibility does not necessarily imply that the density is constant; rather, it may still depend on temperature or pressure. In the current context, compressibility means whether we should solve the continuity equation as \(\nabla \cdot (\rho \mathbf u)=0\) (compressible Stokes) or as \(\nabla \cdot \mathbf{u}=0\) (incompressible Stokes).

This material model is incompressible.

Implements aspect::MaterialModel::Interface< dim >.

|

static |

|

overridevirtual |

Read the parameters this class declares from the parameter file. The default implementation of this function does not read any parameters. Consequently, derived classes do not have to overload this function if they do not take any runtime parameters. On the other hand, most plugins do have run-time parameters, and they may then overload this function.

Reimplemented from aspect::Plugins::InterfaceBase.

|

overridevirtual |

If this material model can produce additional named outputs that are derived from NamedAdditionalOutputs, create them in here. By default, this does nothing.

Reimplemented from aspect::MaterialModel::Interface< dim >.

| double aspect::MaterialModel::ViscoPlastic< dim >::get_min_strain_rate | ( | ) | const |

| bool aspect::MaterialModel::ViscoPlastic< dim >::is_yielding | ( | const MaterialModelInputs< dim > & | in | ) | const |

A function that returns whether the material is plastically yielding at the given input variables (pressure, temperature, composition, strain rate, and so on).

|

private |

Pointer to the object used to compute the rheological properties. In this case, the rheology in question is visco(elasto)plastic. The object contains functions for parameter declaration and parsing, and further functions that calculate viscosity and viscosity derivatives. It also contains functions that create and fill additional material model outputs, specifically plastic outputs. The rheology itself is a composite rheology, and so the object contains further objects and/or pointers to objects that provide functions and parameters for all subordinate rheologies.

Definition at line 242 of file visco_plastic.h.

|

private |

Definition at line 244 of file visco_plastic.h.

|

private |

Whether to use user-defined thermal conductivities instead of thermal diffusivities.

Definition at line 249 of file visco_plastic.h.

|

private |

Definition at line 251 of file visco_plastic.h.

|

private |

Number of phase transitions for each chemical composition (including the background field).

Definition at line 256 of file visco_plastic.h.

|

private |

Total number of phases.

Definition at line 261 of file visco_plastic.h.

|

private |

Object for computing the equation of state.

Definition at line 266 of file visco_plastic.h.

|

private |

Object that handles phase transitions.

Definition at line 271 of file visco_plastic.h.

|

private |

Determines whether to look up the dominant phases for each composition in its respective lookup table.

Definition at line 276 of file visco_plastic.h.

|

private |

Object that handles discrete phase transitions for the rheology if requested by the variable use_dominant_phase_for_viscosity.

Definition at line 281 of file visco_plastic.h.